Asset life extension: OceanTech’s solutions for verifying structural integrity

Underwater inspections and modifications are critical to extending the lifetime of offshore assets. By utilising remotely operated tools, OceanTech is able to verify the integrity of any structure in the splash zone, and perform modifications such as structural reinforcements, anode installations, and caisson replacements.

According to a report by industry group Offshore Energies UK (OEUK), more than 2,000 wells in the UK sector of the North Sea will need to be decommissioned over the next decade. Estimated at a total of $23 billion, the cost burden for plugging wells and removing platforms is set to rise sharply over the next three to four years as more fields stop production, OEUK warns in the report.

As energy companies continue to discover new fields, and advances in technology make it possible to extract more than previously thought, quite a few companies are going against the grain and investing in asset life extension. Equinor’s Statfjord field is perhaps the most obvious example. Originally planned to be shut down in 2022, the current goal is to maintain safe and profitable operations until 2040. The field is estimated to have generated $180bn in income over its lengthy lifespan, and with the planned drilling of 100 new wells, Equinor seems confident that profit remains in the field.

The regulatory requirements for asset life extensions vary by jurisdiction, but they generally include environmental impact assessments, safety inspections, and other reviews to ensure the platform can continue operating safely and in compliance with regulations. Structural integrity inspections play a vital role in these processes. Offshore assets experience harsh environmental conditions, weakening their structural integrity over time.

Structural integrity challenges

The structural integrity of an offshore platform refers to the ability of the structure to withstand various loads, forces, and environmental conditions over its intended lifespan. This includes the ability to resist wind, waves, currents, and fatigue and corrosion damage due to the harsh offshore environment. Common structural integrity challenges to assess in asset life extension processes include:

- Corrosion that causes structures and pipes to weaken and become more prone to failure and leaks

- Fatigue cracking or bending stress, which can compromise the structural integrity of the platform over time

- Degraded anodes on offshore structures, pipelines, and foundations

- Degraded riser protection nets (RPNs) that protect vulnerable risers from impact by errant supply boats

- Possible platform overload due to equipment additions or new work processes

Asset life extension processes involve several key inspection and modification requirements to ensure the asset continues to operate safely and effectively beyond its originally planned design life. This includes inspection of critical components, such as platform structure and mooring systems, and possible structural modifications to ensure the asset can withstand new environmental conditions and support new installations.

OceanTech’s asset life extension services

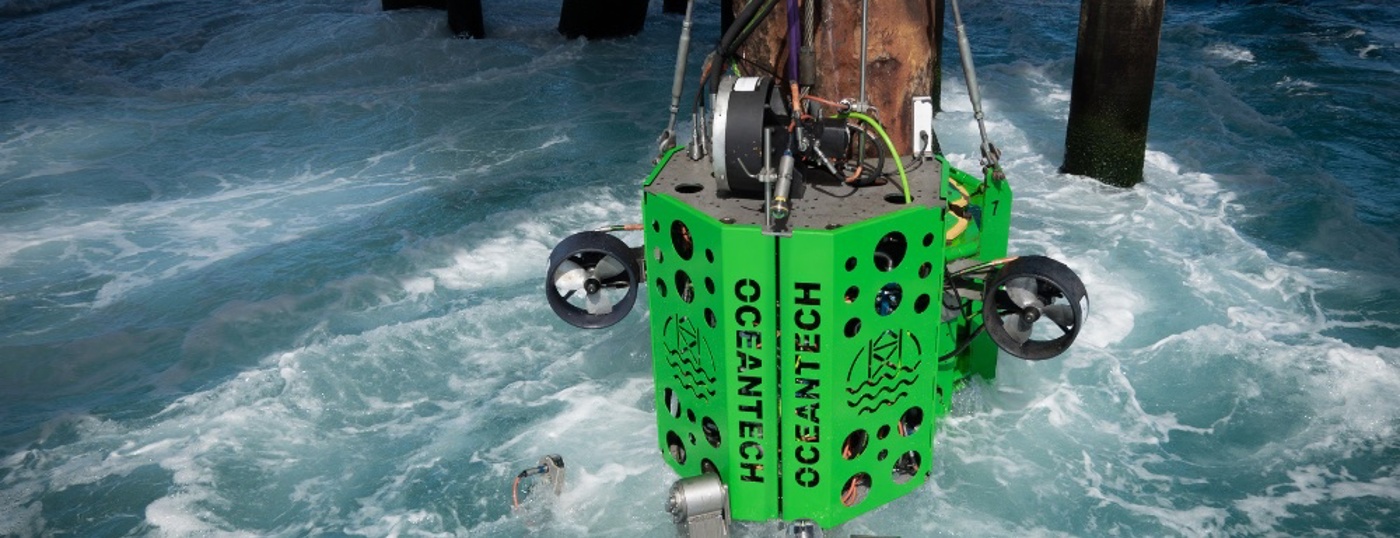

OceanTech’s innovative robotic solutions for splash zone operations are ideal for verifying the integrity of any structure in life extension processes. All of our tools and techniques avoid the use of divers, remotely operated underwater vehicles (ROVs), and support vessels. They also offer access to the splash zone in adverse weather conditions.

Inspection services

OceanTech’s inspection capabilities include visual and non-destructive testing (NDT) services specialised for splash zone and underwater structures. Our robotic solutions provide a fixed, stable platform, enabling the deployment of sensors, cameras, probes, and other inspection tools that would be impossible to use with divers and ROVs. Our inspection toolkit includes techniques such as:

- General visual inspection (GVI)

- Close visual inspection (CVI)

- Cathodic protection (CP) measurements

- Ultrasonic thickness (UT) measurements

- Pulsed eddy current (PEC) thickness measurements

- Alternating current field measurement

Wall thickness measurements and crack detection are particularly important in asset life extension projects. Wall thickness measurements typically use ultrasonic testing or other non-destructive methods (PEC). By using vertical access tools, such as our clamp access tool, the robotic arm can measure the thickness of all steel pipes, check for possible leaks, and discover any degradation. For crack detection, we use our robotised inspection tool. This enables us to detect fatigue cracks, calculate remaining service life, and determine the need for clamps and further monitoring.

Modification services

Modifications to underwater structures in the splash zone are the core business of OceanTech. In asset lifetime extension projects, modification work may include:

- Anode modifications and installations

- Replacing sections of caissons

- Riser guide frame modifications

- Underwater clamp modifications and installations

- Installations of other reinforcements

Recently completed projects include underwater anode installations, fairlead replacements, caisson replacements, and riser protection net replacements for global energy companies such as Equinor, Woodside, and ConocoPhillips. By replacing caissons and clamps, installing structural reinforcements, and modifying or installing new anodes, OceanTech contributes to extending the lifetime of offshore structures worldwide.

Innovation adds robustness and enhanced positioning

At OceanTech, we adopt an innovative approach to tackle our clients’ challenges by continuously improving our tools for year-round use. This can alleviate POB challenges during busy summer months.

Currently, we are finalising a research project with SINTEF, DNV, and ConocoPhillips to further improve our robotised inspection tool. By adding enhanced sensors and enabling autonomous inspections, the new ANDWIS (Automated Non-Destructive Weld Inspection Robot) will be a game-changer in detecting fatigue cracks.

The methods we use to prolong the life of an ageing asset depend on various factors, such as the type of asset, specific company requirements, and regulatory framework. However, inspections and modifications are critical to any asset life extension process.

As the offshore industry strives to prolong the economic viability of its assets, many will operate for longer than initially intended. In fact, certain oil and gas assets have already been in service for over 40 years. Extending the lifespan of an asset means extracting additional value without compromising its original design or structural integrity.